Sanding removes defects and levels ridges.

Sanding lacquer with steel wool.

Sanding sealer powders when sanded.

But you will usually get better results if you sand to 1000 grit first.

Because you are removing much more finish when sanding than when simply rubbing with steel wool the finish should be thicker to begin with or you will likely sand through.

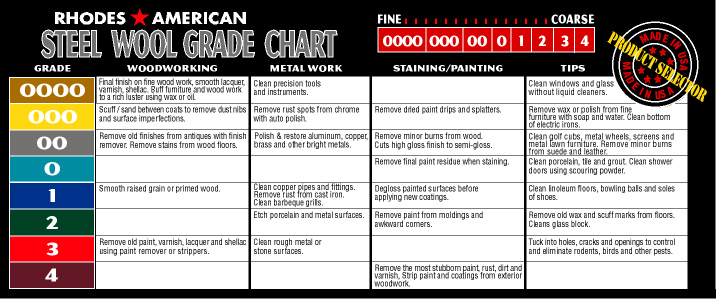

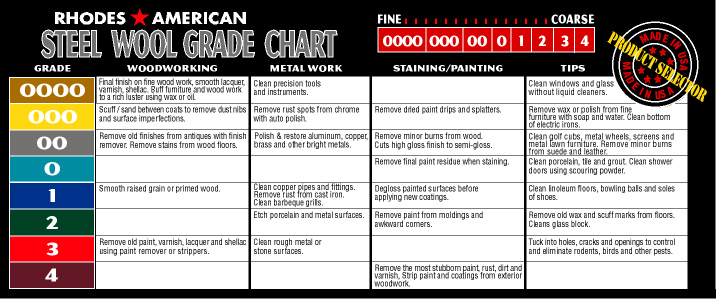

0000 steel wool should be equivalent to 400 600 grit sand paper.

Then rub with 0000 steel wool or with pumice and a mineral oil lubricant using a felt or cloth pad.

The leveled finish is then further abraded with a fine grade 4 0 steel wool to leave a finer and slightly different scratch pattern thus raising the sheen.

In my experience assuming the finish is dry there isn t a difference other than the coarseness of the sand paper or steel wool.

What steel wool are you using.

The very fine strands of steel gently cut into the surface being sanded removing an ultra thin layer.

The steel wool is very fine and will actually scrape off a very fine layer leaving a silky smooth finish often referred to as a hand rubbed finish.

Liberon makes the best steel wool and it isn t too expensive maybe a few dollars more than what they sell at a big box store.

The only drawback with poly is that it is.

Apply the lacquer finish.

It s worthwhile buying a quality steel wool.

You can stop at 600 grit if you intend to rub with steel wool or with pumice.

Sanding sealer is varnish or lacquer with a soap like lubricant included.

The steel wool buffing process is fairly straightforward.

Spraying is the traditional method of applying lacquer but brushable lacquer is an acceptable alternative although it can be a bit more temperamental than spray lacquer.

After carefully wiping off the sanding dust or residue with a damp cloth rub the entire finished surface with steel wool and lubricant in the direction of the grain.

Using steel wood to polish wood might seem out of place and actually harmful to the surface of the wood but it isn t if done properly.

If you re going for a satin finish rubbing out with 0000 steel wool should work.

Using steel wool or sand paper allows you to create a uniform surface for the next coat of polyurethane which generally looks nicer more professionally etc.

The main advantage of using steel wool rather than sandpaper is that the steel wool can compress to almost any shape so it can be used much more easily in hard to reach places as well as on complex shapes such as.

Here s a process for achieving a high satin or semi gloss rubbed sheen on a lacquer coating.

This age old two step technique is commonly used on shellac and lacquer finishes but it can work well on water and oilbased polyurethane too.

With the staining completed apply a light coat of lacquer to the entire project.

Use medium to heavy pressure and try to keep the pressure and the direction of your strokes as consistent as possible.